device

device

Dedicated to providing customers with:

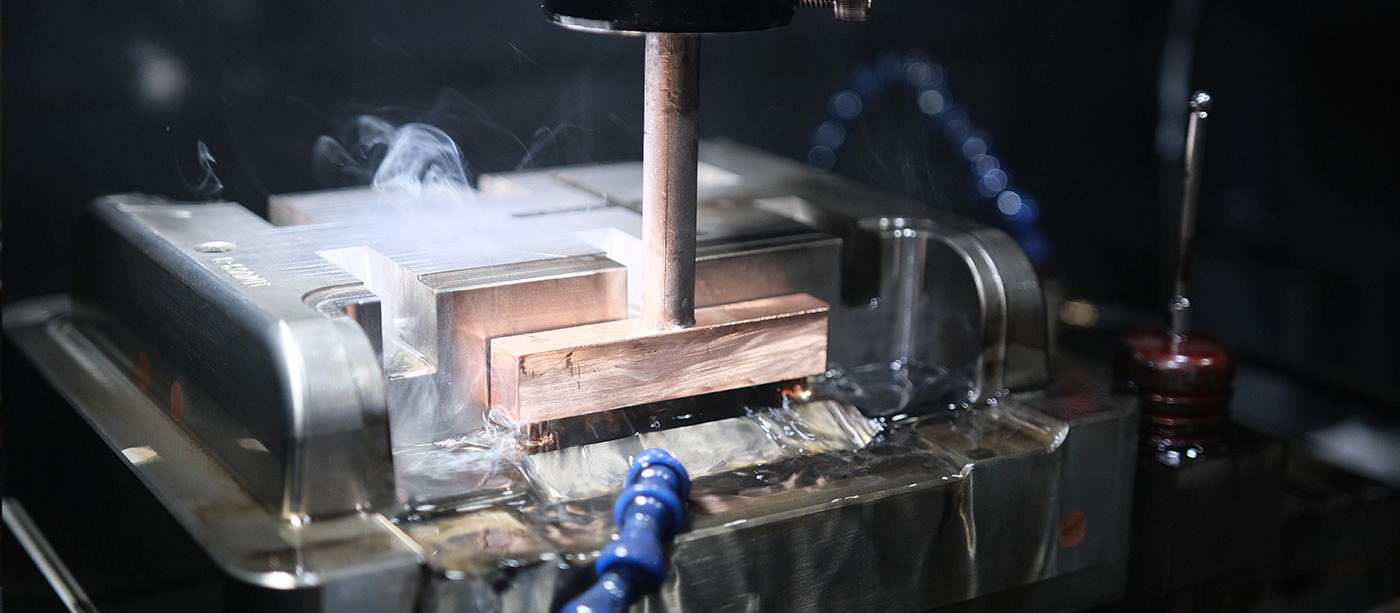

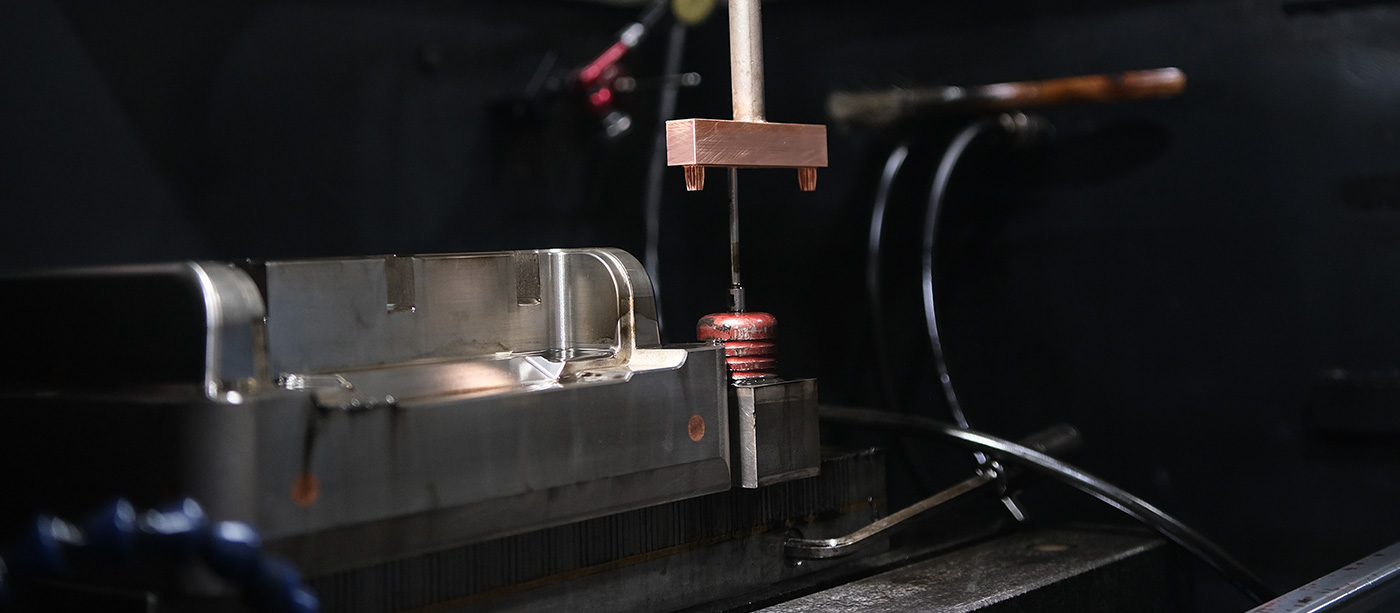

High precision, long lifespan short cycle

Workshop

Quality detection

Equipment list

Before conducting a trial mold, monitor the quality and inspection of the mold processing. With the support of abundant and effective measurement equipment resources and human resources, control various sizes and issues of mold components to ensure a 100% delivery rate of molds. The quality team includes incoming inspection, process inspection, product inspection, electrode inspection, shipment inspection, and quality management system. With the support of various precision measurement equipment resources and qualified quality personnel, it truly realizes strict control of mold production quality from raw materials, process, and final inspection. Through the implementation of the quality management system, the quality control level of the entire company is monitored and improved in real time.

| Device Name | Instrument Name | Number | Manufacturer |

| CNC | 7 units | China | |

| 1 units | Swiss GF, Mikron | ||

| Electric spark pulse | 5 units | Taiwan, China | |

| 2 units | China | ||

| 2 units | Swiss GF Achaemia | ||

| Grinder | 1 units | China | |

| 1 units | Taiwan, China | ||

| 1 units | Okamoto, Japan | ||

| Line cutting | 5 units | China | |

| 2 units | Sodick | ||

| Test equipment | Three-dimensional | 1 units | Hexagon |

| Projection | 1 units | ||

| TESA altimeter | 1 units | ||

| Injection molding equipment | Dual color machine 250Ton | 1 units | Sea to Sky |

| 120-250Ton | 4 units | Sea to Sky | |

| 168Ton | 2 units | Guangdong Jiaming | |

| Milling machines, drilling machines, and other processing equipment. | |||